Cialis ist bekannt für seine lange Wirkdauer von bis zu 36 Stunden. Dadurch unterscheidet es sich deutlich von Viagra. Viele Schweizer vergleichen daher Preise und schauen nach Angeboten unter dem Begriff cialis generika schweiz, da Generika erschwinglicher sind.

Suszenierozpylowe.pl

www.buchi.com Information Bulletin Number 59/2010

Laboratory Scale Spray Drying Of Inhalable Drugs:

A Review

Mini Spray Dryer B�290

Figure 1: Mini Spray Dryer B-290

The Mini Spray Dryer B-290 from Büchi

a compact spray dryer. The residence

The adjustable process parameters

Labortechnik AG is a laboratory scale

time of the drying air within the spray

instrument to perform spray drying

chamber is about 1.5 seconds. The

processes down to 30 mL batch volume

powder col ection is provided by a

• inlet and outlet temperature,

and up to 1 litre of water or organic

glass-made cyclone separator, which

• sample feed rate,

solvent per hour. Thanks to the glass-

is internal y coated with a thin nanosize

• drying gas flow rate and

ware, the complete drying process

antistatic film to reduce powder

• spray gas flow

from the two-fluid nozzle down to the

adhesion to the glass wall. The

powder col ection vessel is visible.

separation works by centrifugal forces

Fine particles are produced because

by virtue of inertia of the solid

of the short residence time in such

Features and benefits

Mini Spray Dryer B-290

Main benefit

for traditional spray drying, established process

Max. inlet temperature

1.0 kg/h, higher for solvents

Nozzle types

two-fluid nozzle, three-fluid nozzle

typical y around 50% - 70%

Min. sample volume

Max. sample viscosity

300 cps (viscous samples and juices possible)

possible to scale-up to kg- and tons-scale

Table 1: Features and benefits of the Mini Spray Dryer B-290

Nano Spray Dryer B�90

Figure 2: Nano Spray Dryer B-90

The new Nano Spray Dryer B-90 is

The liquid sample is fed to the spray

membrane to vibrate, ejecting mil ions

based on a new spray drying concept.

nozzle via a peristaltic pump in a re-

of precisely sized droplets per second

The drying gas enters the apparatus

circulation mode.

with a very narrow distribution. These

from the top where it is heated to the set

The generation of droplets is based on

extremely fine droplets are dried

inlet temperature, flows then through

a piezoelectric driven actuator, vibrating

into solid particles and col ected by

the drying chamber, and exits the spray

a thin, perforated, stainless steel

electrostatic charging and subsequent

dryer at the bottom outlet. The gas is

membrane in a small spray cap. The

deflection to the collecting electrode.

additional y fine filtered before leaving the

membrane (spray mesh) features an

Final y the resulting powder is col ected

instrument. The inlet temperature and

array of precise, micron-sized holes

using a rubber spatula.

outlet temperature are measured just

(4.0, 5.5 or 7.0 μm). The actuator is

after the heater and before the fine filter.

driven at around 60 kHz, causing the

Features and benefits

Nano Spray Dryer B-90

Main benefit

for small quantities, finest particles, highest yields

Max. inlet temperature

Nozzle type

piezoelectric driven vibrating mesh

electrostatic particle col ector

Min. sample volume

Max. sample viscosity

10 cps (diluted samples)

limited by spray head and electrical particle col ector

Table 2: Features and benefits of the Nano Spray Dryer B-90

Laboratory Scale Spray Drying Of Inhalable Drugs: A Review

Author: Dr. Cordin Arpagaus, Dr. Nina

[3, 4]. It has the potential to generate

particles, based on the available RDD

Schafroth and Marco Meuri

highly dispersible powders for inhalation

online proceedings database. The liter-

in the range from 1 to 5 μm size with a

ature review showed breakthrough R&D

particle morphology that can more eas-

innovations in the field of respiratory

The pharmaceutical industry addresses

ily be influenced compared to for exam-

drug delivery with key information about

a number of demands on novel respira-

ple jet mil ing [5].

available spray drying parameters and

ble particulates, which from a process

technology perspective can be broadly

This study reports a review, regarding

Spray drying applications focused

categorized into the areas of: perfor-

research work on particles for inhalation

especial y on anti-asthmatic drugs

mance (e.g. total/local lung deposition,

that have been published in the RDD

[2, 5-9], antibiotics [1, 9-12], proteins,

immediate versus controlled release),

proceedings database, using laboratory

such as insulin [13-15], bovine serum

processing (e.g. achieve flow properties)

scale Büchi Mini Spray Dryer models

albumin [16] or human serum albumin

and stability (e.g. physical/chemical sta-

B-190, B-191 and B-290

[17], antibodies [18] and tuberculosis

bility and activity).

A new trend in pulmonary drug delivery

Literature Review

Various excipients were applied to

is to move from the liquid or pressurised

stabilize drugs during formulation,

formulations to dry powder inhalation

A search query in the RDD online data-

predominately mannitol [13, 14, 17, 18,

formulations. This, in part, is due to the

base with the key word "spray drying"

20], poly(lactic-co-glycolic-acid) PLGA

advantages of dry powder systems, in-

revealed 53 hits. Figure 3 visualizes the

[8, 10, 19, 21], lactose [5, 8, 16] and

cluding breath-actuated inhalation, lim-

distribution of these published papers

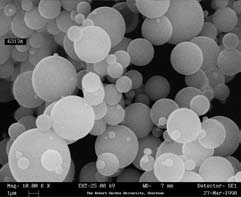

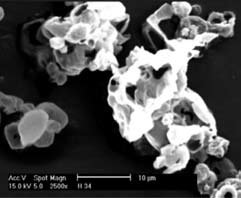

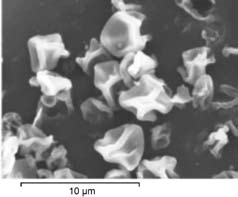

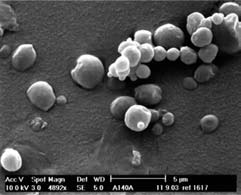

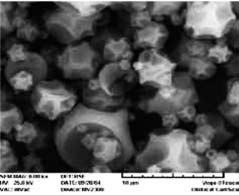

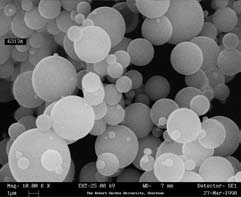

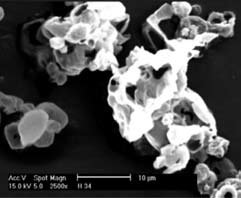

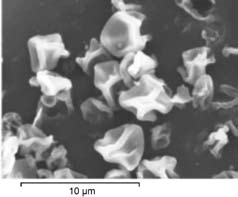

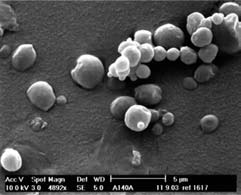

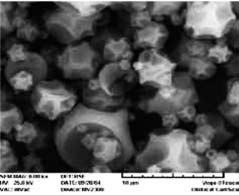

chitosan [7]. SEM photographs of

ited coordination requirements, no pro-

over the last several years. It seems

the spray dried powders exhibited

pel ant requirement and short treatment

that the ful potential of the spray drying

mostly spherical shapes with corrugated

process for dry powder aerosols has

surfaces, resin-like or even hol ow

Spray drying is a simple, rapid, repro-

not been ful y exploited yet. Spray

structures, depending on the sub-

ducible, economic and easy to scale-up

drying has become a well established

stance material and drying conditions

production process [2] that has been in-

technology in pulmonary drug delivery.

(Table 3A and 3B).

tensively studied for pharmaceuticals

The produced particles were in the respi-

and excipients for pulmonary drug de-

Table 3A and 3B reviews the spray

rable size range with roughly 1 - 5 μm

livery in dry powder inhalation systems

drying research with regard to inhalable

aerodynamic diameters. High fine parti-

online database

D

ber of abstracts

ord "spray drying" 4

ith keyw

w 0

published in R

Figure 3: Number of abstracts published in the RDD online database (www.rddonline.com, visited January 8, 2010) with key word "spray drying" (total 53 abstracts)

Particle size, shape,

Carrier and

Spray drying

yield, fine particle

Reference and

application

fraction (FPF) and

emitted dose (ED)

Terbutaline

Spherical particles

Cook et al. 2004

sulphate

University of London

Matrix forming exipients

throat impaction 23.9 % Dryer B-191

School of Pharmacy, UK

4% w/w terbutaline

1 - 15 μm particle size

Terbutaline

Learoyd et al. 2006a

sulphate

6-36% w/w leucine and

gas spray 600 L/min

Aston University,

25-50% w/w chitosan

Hol ow to porous

Salbutamol

particles, reduced

phosphatidylcholine,

Brandes et al. 2004

sulphate

agglomeration tendency Mini Spray

Christian Albrecht

compared to jet-mil ed

calcium chloride

University, Germany

powders, 40% drug

dihydrate, Solkane 227

Spherical particles

Salbutamol

Learoyd et al. 2006b

PLGA, beclomethasone

sulphate

spray gas 600 L/min

Aston University,

dipropionate, PVA,

feed rate 3.2 mL/min

Dryer B-290 Birmingham, UK

Spherical particles

Weiler et al. 2008

Salbutamol

3.2 μm , FPF around

Johannes Gutenberg-

sulphate

Lactose monohydrate

70 %, dispersion

University Mainz,

Boehringer Ingelheim,

Cabral Marques and

Spherical particles

University of Lisbon,

feed rate 5 - 11 mL/min

Raisin-like particles

Hydrochloric acid,

Cagnani et al. 2004

T in < 140 °C

sodium hydroxide,

University of Parma,

respirable particles

polyalcohols, mannitol

Particle diameter < 5.8 μm

Najafabadi et al. 2007

sponge-like morphology

Aqueous solution of

University of Medical

T out 62 - 65°C

suitable for respiratory

insulin and additives

Sciences, Tehran, Iran

spray gas 550 NL/h

(mannitol, polymer)

Pasteur Institute of Iran,

feed rate 3 mL/min

ED 59 - 81% dispersability 57 - 60 %

Drying air humidity <20%

Maltensen and van de

Aqueous solution

T in 75 - 220°C

Resin-like morphology

spray gas 7 - 17 L/min

particle size of 4 μm

University of Copenhagen,

feed rate 2 - 5 mL/min

suitable for inhalation

aspirator 80 - 100%

Spherical to corrugated

Gentamicin

shape particles of

Lechuga-Ballesteros et al.

Gentamicin with small

amounts of trileucine

Nektar Therapeutics, USA

Table 3A: Literature review of spray dried inhalable products using the laboratory scale Büchi Mini Spray Dryer models B-190, B-191 and B-290. "Part 1"

Particle size, shape,

Carrier and

Spray drying

yield, fine particle

Reference and

application

fraction (FPF) and

emitted dose (ED)

Doxycycline

Traini et al. 2007

Corrugated particles

University of Sydney,

Monash University,

Victoria, Australia

Bain et al. 2002 Quintiles (UK) Ltd,

Rifampicin

Spherical particles

Poly(D,L-lactide) (PDLLA)

University of Strathclyde,

Glasgow, Scotland

John Moores University, Liverpool, England

Cefotaxime

Spherical particles

Najafabadi et al. 2005

University of Medical

T out 87 - 89 °C

better aerolisation

Sciences, Tehran, Iran

compared to jet mil ing

Spherical particles with

Tobramycin

corrugated surfaces

Parlati et al. 2008

0.25 - 2.0 % sample

< 3.0 μm size yield 60 %

University of Sydney,

in vitro drug deposition

Corrugated particles

Bovine Serum

Lactose / Brij 76

5.4 / 12.8 μm size

Li and Sevil e 2008

Aston University,

recovery of drug after

spray gas 600 L/h

inhalation >95 %

Schüle et al. 2004

No change in secondary Mini Spray

University of Munich,

spray gas 670 L/h

proteins structure

Dryer B-290 Boehringer Ingelheim,

feed rate 3 mL/min

Protein/mannitol ratio

Zimontkowski et al. 2005

(antibody) and

Spherical particles

University of Bonn,

Human Serum

spray gas 700 L/h

Boehringer Ingelheim,

feed rate 9 mL/min

Garcia-Contreras et al.

Proteins secreted Poly

1.95 μm particle size

(lactic-co-glycolic acid)

feed rate 7 ml/min

University of North

activity > 93 %

Spherical particles

Lysozyme

200 mL solutions of

5 μm particle size

Shoyele et al. 2008

(enzyme for

University of Bradford, UK

T out 50 ± 2°C

3M Drug Delivery

spray gas 500 L/h

phosphate buffer

12 weeks storage

feed rate 5 mL/min

66% retained enzymatic

Mean size 4 - 10 μm

Colombo et al. 2008

Morphine

concentration of morphine

satisfactory morphine

University of Parma

spray gas 600 L/h

HCl, mannitol and lecithin

stability in agglomerated Dryer B-191

University of Salerno

feed rate 3.2 mL/min

University of Ferrara, Italy

Mannitol

concentrations up

Morton et al. 2008

Mannitol with 1 - 10%

to 35 ppm in air

Monash University,

w/w different additives

feed rate 0.1 mL/s

mean particle size

Victoria, Australia

Table 3B: Literature review of spray dried inhalable products using the laboratory scale Büchi Mini Spray Dryer models B-190, B-191 and B-290. "Part 2"

cle fractions were achieved, ranging

sulphate nanoparticles (an anti-asthma-

acting inhaled drug particles (about

from 30 - 60% [6-8, 16] to over 85%

tic drug) into microparticles [2].

0.5 - 3.3 μm which represents

[13]. Inhaler emitted powder doses of

Physically and chemically stable

deposition in the lung alveoli).

over 90% were reported [2, 7, 8]. Amor-

non-cohesive spray dried particles,

The key benefits of this technology are

phous powders were typical y generated

with smal aerodynamic diameters

the possibilities to control the size and

due to the short drying time in the labo-

were designed to be efficiently delivered

morphology of the particles under a

ratory scale spray dryers [3, 22]. Aero-

as a dry powder aerosol [11]. Spray

relatively gentle processing method.

solized powder clouds with maximal

drying produced powders with superior

Indeed, this method has been proven

volume concentrations of up to 35 ppm

biochemical stability upon formulation

for the preparation of heat-sensitive

particles in air were achieved [20].

compared to spray freeze drying;

materials such as protein based drugs.

Cefotaxime sodium

(Bain et al. 2002)

(Cagnani et al. 2004)

(Najafabadi et al. 2005)

(Traini et al. 2007)

(Brandes et al. 2004)

(Cook et al. 2004)

(Learoyd et al. 2004)

(Weiler et al. 2008)

Figure 3: SEM photographs of inhalable spray dried powder from literature.

Compared to jet mil ed samples, higher

although with less efficient aerosol

While the traditional bench-top spray

fractions of potential y inhalable aerosol

properties [24]. Sustained release of

dryers have been shown capable

particles of antibiotic cefotaxime

highly dispersible amino acid leucine

tools for the laboratory aim generation

sodium were measured for spray dried

incorporated PLGA powders was

of respiratory sized particles, the area

formulations [23]. Deagglomeration

exhibited over several days [8].

of process technology is ever-evolving.

of spray dried protein formulations

The Nano Spray Dryer B-90 offers new

was possible [17]. Higher powder

possibilities in the field of laboratory

dispersibility of spray dried powders

scale spray drying and eliminates

compared to jet mil ed particles was

Spray drying is a very useful technique

some weak points of traditional spray

explained by their spherical shape

to produce inhalable dry powders with

dryers; including increased recovery

and therefore smaller surface contact

predetermined specifications. There

(up to 90%), smal quantity production

is significant research activity in dry

(100 mg amounts) and highly definable

powder aerosol formulation to treat

particle size ranges (300 nm - 5 μm) [25].

Particularly, high values of respirable

several diseases including asthma,

fractions were found for insulin because

tuberculosis, diabetes and bacterial

of the spray dried particle size [13]. The

infection in the lung. Spray drying offers

capability for inhalation with relatively

great potential to these applications

high drug loading was shown, for

because of the easy achievement of the

example by incorporation of terbutaline

accepted optimum size range for local y

[10] Bain, D. F. et al. (2002),

formulations for spray drying",

"Biodegradable microspheres for

RDD 4 , 377-380.

[1] Parlati, C. et al. (2008), "In vitro

control ed intra-pulmonal delivery of

evaluation of co-processed antibiotic

Rifampicin to treat tuberculosis",

[19] Garcia-Contreras, L. et al. (2004),

for inhalation", RDD, 907-910.

RDD 8, 561-563.

"Formulation strategies for a novel

inhaled tuberculosis vaccine",

[2] Cook, R. O. et al. (2004), "Sustained

[11] Lechuga-Bal esteros, D. et al.

RDD 4, 877-880.

release microparticles containing

(2004), "Designing stable and high

drug nanoparticles for pulmonary

performance respirable particles of

[20] Morton, D.A.V. et al. (2008),

administration", RDD 4, 777-780.

pharmaceuticals", RDD IX, 565-568.

"Investigating Effects of Surface

modifications on an Mannitol Dry

[3] Dem, C. et al. (2006),

[12] Traini, D. et al. (2007), "Co-spray

Powder Inhaler Plume by Laser

"Understanding the spray dry design

dried antibiotics for dry powder

Diffraction", RDD, 649-653.

process through single droplet

inhalation delivery", RDD Europe,

investigations", RDD, 257-265.

[21] Arpagaus, C. and Schafroth, N. (2009), "Laboratory scale spray

[4] Hickey, A.J. et al. (1996),

[13] Cagnani, S. et al. (2004), "A novel

drying of biodegradable polymers",

Pharmaceutical inhalation aerosol

spray dried formulation for

RDD Europe 2009, 269-274.

technology, Marcel Dekker,

pulmonary administration of Insulin",

RDD 4, 813-816.

[22] Colombo, P. et al. (2006), "Nasal powders of morphine microcrystal

[5] Weiler, C. et al. (2008), "Dispersibility

[14] Najafabadi, A.R. et al. (2007), "The

agglomerates", RDD, 885-887.

of jet mil ed vs. spray dried powders ",

effect of polymer on the properties

RDD Europe, 571-575.

of insulin/mannitol spray dried

[23] Najafabadi, A.R. et al. (2005),

powder for inhalation", RDD Europe,

"Evaluation of cefotaxime sodium

[6] Brandes, H.G. et al. (2004),

microparticles for respiratory drug

"Particle design to improve

delivery", RDD Europe, 265-268.

pulmonary delivery of powdered

[15] Maltesen, M.J. and Van de Weert,

medications," RDD 4, 229-231.

M. (2008), "Particle size of spray

[24] Shoyele, A.S. et al. (2008), "A

dried insulin evaluated by NIR

comparative study on the bio-

[7] Learoyd, T.P. et al. (2006a),

spectroscopy", RDD, 827-830.

chemical stability and pharmaceutical

"Sustained drug delivery from

performance of excipient-free

chitosan-based respirable spray-

[16] Li, H.Y. and Sevil e, P.C. (2008),

spray dried and spray freeze dried

dried powders ", RDD, 441-444.

"Preparation of pMDI protein

protein pMDIs", RDD, 823-826.

formulations using surfactant-

[8] Learoyd, T.P. et al. (2006b),

coated spray dried powders", RDD,

[25] Schmid, K. et al. (2009),

"Leucine-modified PLGA-based

"Evaluation of a vibrating mesh

respirable spray-dried powders for

spray dryer for preparation of

sustained drug delivery", RDD,

[17] Zimontkowski, S. et al. (2005),

submicron particles", RDD Europe,

"Dispersion characteristics of spray

dried protein powder formulations

[9] Cabral Marques, H. M. and Almeida

assessed by laser diffraction and

Coimbra, R. N. M. A. (2009),

SEM", RDD Europe, 273-276.

"Preparation and in vitro evaluation

of cyclodextrin/beclomethasone

[18] Schüle, S. et al. (2004),

complexes as dry powder inhaler

"Determination of the secondary

formulations", RDD Europe, 413-417.

protein structure of IgG1 Antibody

BÜCHI Labortechnik AG

BUCHI UK Ltd.

BUCHI Hong Kong Ltd.

Nihon BUCHI K.K.

BUCHI Canada Ltd.

CH – 9230 Flawil 1

GB – Oldham OL9 9QL

J – Tokyo 110-0008

CDN – Thornhil , Ontario L4J 6Z2

T +41 71 394 63 63

T +44 161 633 1000

T +81 3 3821 4777

T +1 416 277 7407

F +41 71 394 65 65

F +44 161 633 1007

F +81 3 3821 4555

F +1 905 764 5139

BÜCHI Labortechnik GmbH

BÜCHI Labortechnik GmbH

BUCHI India Private Ltd.

D – 45127 Essen

RC – 500052 Shanghai

IND – Mumbai 400 055

USA – New Castle,

e subject to change without notice/ Quality Systems ISO 9001

Freecall 0800 414 0 414

T +86 21 6280 3366

T +91 22 667 18983 / 84 / 85

T +49 201 747 490

T +31 78 684 94 29

F +86 21 5230 8821

F +91 22 667 18986

Toll Free: +1 877 692 8244

F +49 201 237 082

T +1 302 652 3000

F +1 302 652 8777

Technical data ar

BUCHI Sarl

BÜCHI Italia s.r.l.

BUCHI (Thailand) Ltd.

F – 94656 Rungis Cedex

I – 20090 Assago (MI)

T – Bangkok 10600

T +39 02 824 50 11

T +66 2 862 08 51

F +66 2 862 08 54

11592334 The English version is the original language version and serves as basis for all translations into other languages.

We are represented by more than 100 distribution partners worldwide. Find your local representative atwww.buchi.com

Source: http://suszenierozpylowe.pl/wp-content/uploads/2015/09/B-290_BB_59_Laboratory_Scale_Spray_Drying_of_inhalable_drugs_en_01.pdf?4db01d

Asian Transactions on Basic and Applied Sciences (ATBAS ISSN: 2221-4291) Volume 02 Issue 01 Development of Antidiabetic Active Compounds from Ethyl Acetate Extract of Acorus calamus L. Sri Hartati, Rizna T. Dewi, A. Darmawan and Megawati diabetes mellitus in the World. In the year 2000, there are Abstract— In research development of herbal medicine from

HEAVY DUTY SUBMERSIBLE TRANSCEIVER VERTEX STANDARD CO., LTD.4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, JapanVERTEX STANDARDUS Headquarters10900 Walker Street, Cypress, CA 90630, U.S.A.YAESU EUROPE B.V.P.O. Box 75525, 1118 ZN Schiphol, The NetherlandsYAESU UK LTD.Unit 12, Sun Valley Business Park, Winnall CloseWinchester, Hampshire, SO23 0LB, U.K.VERTEX STANDARD HK LTD.Unit 5, 20/F., Seaview Centre, 139-141 Hoi Bun Road,Kwun Tong, Kowloon, Hong Kong